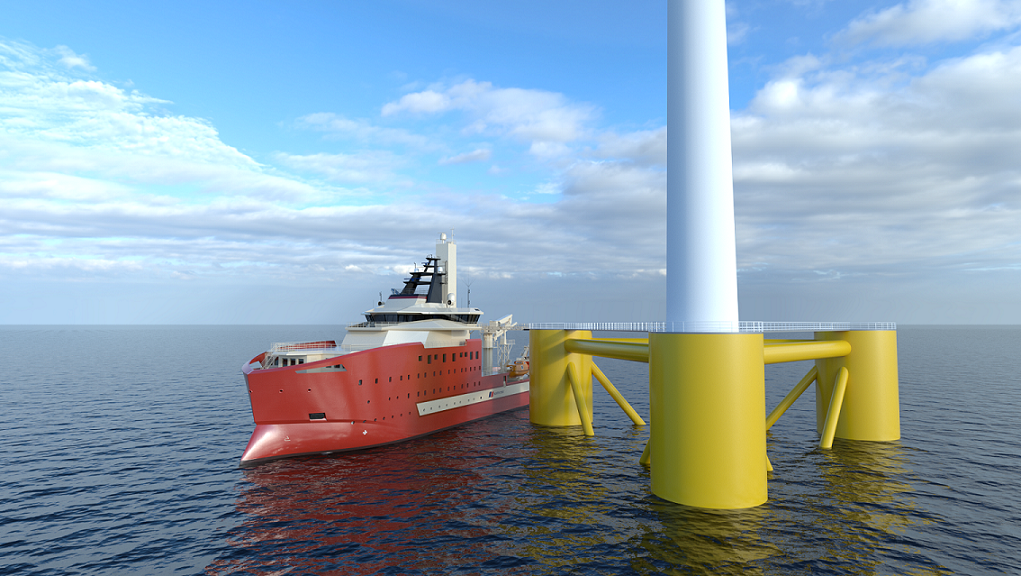

North Star, a leading service operations vessel (SOV) operator in the UK’s renewables industry, has activated a major industry collaboration aimed at solving one of the floating wind’s most pressing challenges: the delivery of high-performance operations and maintenance ships tailored for floating offshore wind farms.

The firm has signed memorandum of understanding with MO4, Principle Power, SMST, VARD, and Voith Group, to establish a dedicated working group of industry experts to help fast-track the design and testing of a new SOV concept. Together, the six organisations have committed to developing a detailed, high-performance ship design to meet the needs of commercial-scale projects, such as the 17GW of floating projects awarded in the ScotWind leasing round.

As offshore wind moves into deeper waters with floating wind turbines located far from shore, the sector faces significant logistical and operational challenges that must be addressed efficiently and cost effectively. While the industry has demonstrated the ability to safely complete transfers from traditional SOVs to floating wind platforms, there is room for improvement in transfers where both the vessel and platform are dynamic and in motion.

Commercial-scale projects provide the opportunity to optimise these transfers by enabling the development of bespoke SOVs operated under long-term contract that specifically address the local challenges and the requirements of floating wind project operators. This collaboration seeks to capitalise on this opportunity by delivering an SOV design that sets a new industry benchmark for safety, performance, and efficiency.

North Star’s renewables & innovations director Andrew Duncan said: “Floating offshore wind presents both challenges and opportunities, and through this collaboration, we can innovate, and design a solution specifically tailored for GW-scale projects. Our goal is to create an innovative, best-in-class ship design that supports the rapid expansion of floating wind technology. By pushing the boundaries of what’s possible, we can ensure that our future SOVs deliver the highest levels of safety, efficiency, and operational flexibility, ultimately paving the way for a more sustainable energy future.”

The partnership’s key contributions include:

- North Star with its extensive market intelligence and operational experience, will lead the vessel design process, ensuring that logistics and service needs are fully integrated to meet real-world demands in the field.

- Digital twin and AI decision support software firm MO4, will be responsible for assessing the workability of the proposed SOV concept, focusing on vessel motions, gangway performance, and the movement range of the floating wind turbine foundations.

- Principle Power will contribute its 15 years of experience designing, deploying, and operating floating wind platforms to provide critical data on the range of motions expected from WindFloat® platforms and to define operational use cases for inspection, maintenance, and repair, ensuring that the SOV is optimised for the next generation of floating wind projects

- International offshore equipment design and build specialist SMST, will bring its expertise in gangway technology, providing essential data on different walk-to-work options, workability parameters, and solutions for landing height adjustments to ensure safe and efficient personnel transfers

- As key integrator, VARD, a major global designer and specialised vessel shipbuilder, will combine inputs from all partners to develop a cohesive floating offshore wind ship design, ensuring that every aspect is optimised for performance and workability.

- Global technology company Voith Group, will contribute propulsion options, selecting the most suitable DP systems to maintain stability and performance in the challenging environment of floating offshore wind.

Andrew Duncan concluded: “We look forward to leveraging our collective expertise to drive this floating wind innovation forward. The detailed ship design will be put to the test through rigorous workability assessments, ensuring that it meets the highest standards of performance, safety, and efficiency before being implemented in future floating wind projects.”