- Comprehensive consultancy, procurement and construction services for pioneering liquid air energy storage facility in the UK

- Leveraging Bilfinger’s deep industrial expertise to propel significant advancement in sustainable energy storage technology

- Significantly contributing to the UK’s renewable energy goals and grid stabilisation efforts

- Dedicated team of approximately 200 Bilfinger professionals deployed at the customer’s site

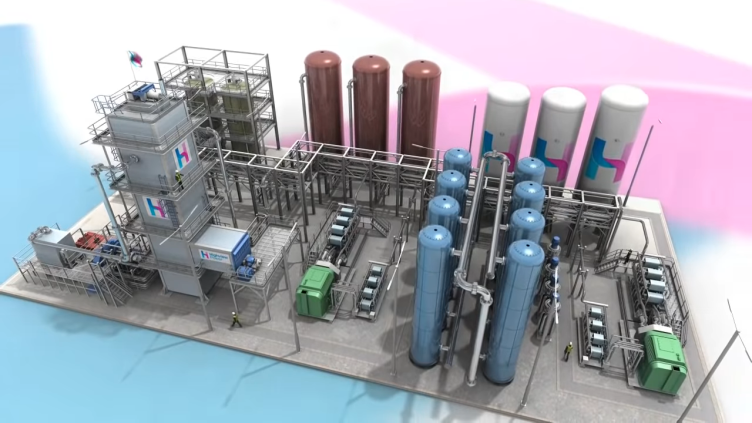

Manchester, England. Bilfinger collaborates with UK long duration energy storage business Highview Power to pioneer the construction of the UK’s first commercial liquid air energy storage facility, aimed at converting surplus electricity into liquid air for storage. The transformative facility will enhance sustainability by storing enough renewable energy equivalent to the electricity used by 1 million homes over an hour. Highview Power’s facility will also provide critical grid stabilisation services. Bilfinger’s Engineering, Automation & Projects UK business stream, having already provided consultancy services during the pre-construction phase, will be responsible for comprehensive procurement and construction services for the plant’s realisation.

The scope of Bilfinger’s services ranges from the procurement of steel to extensive plant construction services, including mechanical, electrical, instrumentation, insulation, painting and structural steel work, along with the overall management of all aspects of construction, including civil works and equipment installation. As principal contractor, Bilfinger is committed to ensuring the highest safety standards on site.

Darren Clement, Vice President, Bilfinger Engineering, Automation and Projects UK, said: “Highview Power’s collaboration with Bilfinger represents a pivotal moment in the energy transition. By leveraging our industrial expertise, this project will see Bilfinger significantly contribute to the nation’s renewable energy goals and grid stabilisation efforts.

“With a dedicated team of approximately 200 Bilfinger employees deployed at the customer’s site, we’re excited to deliver this transformative project.”

The planned large-scale plant with an output of 50 MW and a capacity of 300 MWh is based on Highview Power’s proprietary long duration energy storage system, which utilises liquid air as its storage medium. The system compresses air, which liquefies and can be then stored at low pressure in tanks for weeks. Upon exposure to ambient temperature, the liquid air reverts to its gaseous state, expanding 700-fold and powering a turbine to generate electricity – without combustion. The system is designed to serve as a buffer for surplus electricity from renewable sources.

Approximately 200 Bilfinger employees will work on the contract, focusing on extensive piping and steelwork specially insulated for cryogenic temperatures. Prefabrication will be carried out in Bilfinger’s own local workshops, ensuring a streamlined and efficient process. Leveraging its extensive expertise, Bilfinger has demonstrated its flexibility in meeting the unique challenges of the project, such as reorganising construction sequences to accommodate the installation of the 40 m long, heavy liquid air storage tanks, which exceed the capabilities of conventional cranes.

“We value Bilfinger as a solution provider and are pleased to have their adaptable and dedicated support as we deliver our first commercial facility. Our first project in Carrington will be the foundation for our full scale roll-out in the UK and expansion with partners to share this British technology internationally,” says Highview Power CEO Richard Butland.

Sandy Bonner, President, Bilfinger Engineering & Maintenance UK, added: “As the world derives more and more of its electricity from renewable sources, there’s a growing need for technologies that can capture and store it. We are excited to partner with Highview Power in pushing the boundaries of sustainable energy storage technology and to bring our extensive expertise in the energy industry to this effort.”

Bilfinger has been a long-standing partner to the energy industry, offering support in designing and constructing new plants as well as the optimising, modifying or decommissioning existing facilities. Recent contracts include providing EPCm services for a hydrogen pilot project in a cavern storage facility for Uniper, fabricating pressure piping for a new pump-turbine unit at the Kruonis pumped storage hydropower plant in Lithuania and delivering turnkey construction of a district heating storage facility for Stadtwerke Leipzig GmbH.